Service Max J1939-J1708

126 $ Original price was: 126 $.105 $Current price is: 105 $.

Brand: Service Max J1939-J1708

Version: Latest version

File Size: Approximately 190 MB

License Time: 2 year

Software Type: Professional diagnostic and programming tool

Region: Global

OS Support: Windows 10 and 11

Category: All Product

Size Installed: Approximately 1.3 GB

Database Language: English

Interface Language: English

Service Max J1939-J1708 is a revolutionary protocol designed for heavy-duty vehicles, providing seamless communication between different components and systems. Its significance cannot be understated as it enhances the efficiency of diagnostics and data transmission within these complex machines. In this article, we delve deep into Service Max J1939-J1708, exploring its features, benefits, operational mechanics, applications, troubleshooting strategies, installation guidelines, and future prospects.

Introduction to Service Max J1939-J1708

Understanding the intricate details of Service Max J1939-J1708 is crucial for anyone involved in the automotive industry, especially in fields related to heavy-duty equipment. This protocol operates on two foundational standards: J1939 and J1708, which are developed by the Society of Automotive Engineers (SAE).

J1939 is primarily used for networking among commercial vehicles, allowing various electronic control units (ECUs) to communicate effectively. It employs a CAN bus that ensures high-speed data transfer over short distances, particularly suitable for real-time applications. On the other hand, J1708 serves as a serial communication standard, focusing on low-speed data needs.

The integration of these two protocols into Service Max creates an efficient framework that addresses the complexities associated with vehicle diagnostics and maintenance. Whether it’s monitoring engine performance, diagnosing faults, or managing fuel consumption, understanding how Service Max J1939-J1708 functions is essential for enhancing vehicle reliability and safety.

What is J1939?

To grasp the essence of Service Max J1939-J1708, comprehending the J1939 protocol is necessary. J1939 is designed to facilitate communication among ECUs in heavy-duty vehicles. It supports multiple network nodes, enabling them to transmit and receive messages that inform about operational parameters like speed, temperature, and diagnostic trouble codes (DTCs).

The architecture of J1939 includes several aspects such as message prioritization, which ensures critical information is transmitted without delay. The protocol also utilizes a standardized message format, making it easier for different manufacturers to produce compatible devices that can interface with one another seamlessly.

The flexibility of J1939 allows for various application layers, which can be tailored according to specific requirements, ensuring that it remains relevant even as technology evolves.

What is J1708?

In contrast, J1708 focuses on simpler, lower-speed communication. It’s often used in conjunction with J1939, particularly when dealing with legacy systems or when cost-effective solutions are required. J1708 operates on a half-duplex system, meaning communications can only occur in one direction at a time.

J1708 is characterized by its use of ASCII characters, allowing for straightforward message interpretation. While it may not support the robustness of J1939’s capabilities, it still plays a significant role in many vehicle systems that do not require high-speed communication.

The marriage of J1939 and J1708 in Service Max allows users to harness the advantages of both protocols, ensuring comprehensive vehicle diagnostics and management functionalities.

Key Features of Service Max J1939-J1708

Service Max J1939-J1708 offers a plethora of features that streamline the communication processes in heavy-duty vehicles. Understanding these key attributes is vital for leveraging the full potential of the protocol.

Comprehensive Diagnostic Capabilities

One of the standout features of Service Max J1939-J1708 is its robust diagnostic capabilities. It enables quick identification of issues within the vehicle systems, significantly reducing downtime during repairs.

The protocol provides access to DTCs generated by the vehicle’s ECUs. By retrieving these codes, technicians can accurately pinpoint problems, leading to targeted repairs rather than guesswork. This feature alone saves both time and money, enhancing operational efficiency.

Moreover, the ability to monitor real-time data from various sensors allows for proactive maintenance, ensuring that minor issues are addressed before they escalate into major failures. This predictive approach is invaluable in fleet operations, where vehicle reliability is paramount.

Enhanced Data Transmission

Data transmission is another cornerstone feature of Service Max J1939-J1708. The combination of J1939’s CAN bus technology with J1708’s serial communication provides a flexible and robust framework suited for diverse applications.

With J1939, high-speed messages can be transferred efficiently, allowing for real-time monitoring and control of various vehicle systems. Conversely, J1708 offers a reliable means of communicating less urgent information without compromising the performance of the more critical systems.

This dual capability ensures that users can have continuous access to essential data while also maintaining adequate communication with legacy systems, thus extending the lifespan of older vehicles and their components.

Compatibility Across Multiple Platforms

Another impressive feature of Service Max J1939-J1708 is its ability to function across various platforms, including different makes and models of heavy-duty vehicles. This compatibility is crucial given the diversity of equipment in the field.

By adhering to established standards set forth by SAE, Service Max ensures that different manufacturers’ devices can communicate effectively. This interoperability reduces hurdles for fleet operators who manage a mixed fleet of vehicles.

Such compatibility also extends to software used for diagnostics and repair. Many aftermarket tools are designed to work with J1939 and J1708, further enhancing the usability and flexibility of the Service Max solution.

User-friendly Interface

Finally, the user interface provided by Service Max J1939-J1708 is often praised for its simplicity and intuitiveness. A user-friendly design is essential, especially when technicians are under pressure to diagnose and resolve issues quickly.

Many diagnostic tools equipped with Service Max offer visual representations of data, making it easier for users to understand complex information at a glance. Additionally, software updates and enhancements are typically straightforward, ensuring that users can benefit from the latest features without extensive training.

These combined features make Service Max J1939-J1708 a powerful tool in the realm of vehicle diagnostics and management.

Benefits of Using Service Max J1939-J1708

Embracing Service Max J1939-J1708 brings a wide array of benefits to fleet operators, vehicle manufacturers, and mechanics alike. Understanding these advantages can help stakeholders make informed decisions about integrating this protocol into their operations.

Improved Operational Efficiency

One of the most significant benefits of Service Max J1939-J1708 is enhanced operational efficiency. With its advanced diagnostic capabilities, vehicles can undergo quicker and more accurate assessments.

Fleet managers can rely on real-time data to monitor vehicle performance, allowing them to make data-driven decisions regarding maintenance schedules and resource allocation. This proactive approach minimizes unplanned downtimes, which can severely disrupt operations and impact profitability.

Furthermore, accessing historical data through Service Max aids in identifying patterns in vehicle performance, allowing for better long-term planning and strategy formulation.

Cost Savings

Implementing Service Max J1939-J1708 can lead to substantial cost savings in various ways. First, the ability to perform precise diagnostics reduces the likelihood of unnecessary repairs and parts replacement.

Instead of labor hours spent on trial-and-error methods, technicians can quickly identify the root cause of issues. This efficiency translates into reduced labor costs, as well as minimized expenses related to inventory management and parts procurement.

Additionally, the predictive maintenance capabilities enabled by Service Max ensure that vehicles remain operational longer, reducing costs associated with downtime and vehicle replacement.

Enhanced Safety

Safety is always a priority in the transportation industry, and Service Max J1939-J1708 contributes to this aspect significantly. By enabling thorough monitoring of critical vehicle systems—such as brakes, steering, and engine performance—potential hazards can be identified before they lead to accidents.

Regular diagnostics and real-time monitoring mean that safety issues can be addressed promptly, ensuring that vehicles remain compliant with safety regulations. Fleet operators can maintain a high safety standard, protecting their drivers, cargo, and other road users.

Streamlined Compliance with Industry Standards

The construction of Service Max J1939-J1708 adheres to established industry standards, facilitating compliance with regulatory mandates. As governmental bodies impose stricter rules concerning emissions, safety, and operational efficiency, having a reliable diagnostic tool becomes increasingly important.

Service Max assists operators in meeting these requirements by providing the necessary data to demonstrate compliance during inspections. This capability not only avoids penalties but also positions companies as responsible players in the industry.

How Service Max J1939-J1708 Works

Understanding the operational mechanics of Service Max J1939-J1708 requires delving into the technical underpinnings of both the J1939 and J1708 protocols.

Communication Architecture

At its core, Service Max J1939-J1708 relies on a hybrid communication architecture that combines the strengths of both J1939 and J1708. The J1939 component uses a Controller Area Network (CAN) bus for high-speed data exchange among multiple ECUs, while J1708 uses a serial connection to accommodate lower-speed communication.

The CAN bus allows for efficient message handling, with a focus on message priority. This arrangement helps ensure that timely and critical data—from engine parameters to fault codes—is transmitted with minimal latency.

On the other hand, the serial communication of J1708 complements this high-speed setup, making it possible to connect and interact with older vehicles and systems that might not support CAN bus technology. This dual approach allows for greater flexibility in vehicle diagnostics.

Message Structure

Service Max operates using a structured message format that facilitates effective communication among ECUs. Each message comprises specific fields, including identifiers, priorities, and data payloads.

Messages dispatched through the J1939 protocol include identifiers that categorize the type of data being sent. For instance, different identifiers exist for engine data, transmission data, etc. Prioritization ensures that more critical messages take precedence, allowing for seamless operation even during busy communication periods.

In the case of J1708, messages are formatted in ASCII, which simplifies the process of interpreting the data received. This structure fosters easy integration with diagnostic tools and software, enabling technicians to access and analyze information effortlessly.

Data Retrieval and Analysis

Once the communication architecture and message structures are in place, the next step involves data retrieval and analysis. Service Max enables technicians to extract valuable data from the ECUs, allowing for comprehensive diagnostics.

Mechanics can utilize specialized diagnostic tools equipped with Service Max to query ECUs for real-time parameters or stored DTCs. This accessibility transforms the diagnostic process, shifting it towards a data-centric model that prioritizes informed decision-making.

After retrieving the data, analysis tools can generate reports, highlight trends, and visualize performance metrics. These insights empower technicians with the knowledge needed to make strategic maintenance decisions, ultimately boosting vehicle reliability.

Comparing Service Max J1939-J1708 with Other Protocols

When evaluating Service Max J1939-J1708, it’s helpful to compare it to other protocols utilized in the automotive space. This comparison highlights the unique strengths and limitations of Service Max.

OBD-II Protocol

The OBD-II protocol is widely recognized in passenger vehicles for monitoring emissions and general vehicle performance. While it shares some similarities with J1939, especially in terms of diagnostics, it primarily focuses on light-duty vehicles.

Service Max J1939-J1708 surpasses OBD-II in terms of communication speed and complexity, making it more suitable for heavy-duty applications. Additionally, J1939’s capabilities to handle multiple ECUs simultaneously are far superior to those of OBD-II.

However, OBD-II has an edge in terms of ease of use, particularly for consumer-level diagnostics, thanks to its widespread familiarity among technicians and simplicity in connecting scanning tools.

ISO 14229 – Unified Diagnostic Services (UDS)

ISO 14229, known as Unified Diagnostic Services (UDS), is another protocol designed for diagnostics in automotive systems. UDS is versatile and can support various vehicle architectures, making it appealing for modern vehicles.

While Service Max J1939-J1708 excels in addressing the specific needs of heavy-duty trucks, UDS offers broader applicability across different vehicle types. However, for applications requiring rigorous real-time data monitoring and communication among numerous ECUs, Service Max stands out due to its high-speed capabilities and reliability.

Ethernet-based Protocols

As technology advances, Ethernet-based protocols are emerging in the automotive domain, promising even faster and more efficient communication. These newer protocols aim to support the increasing demand for data-heavy applications, such as autonomous driving and advanced driver-assistance systems (ADAS).

While Ethernet protocols may eventually overshadow J1939 and J1708, the latter remains highly relevant for existing heavy-duty vehicle infrastructures. Retrofitting older vehicles with Ethernet technology presents challenges, making Service Max J1939-J1708 a practical choice for legacy systems.

In conclusion, while alternative protocols offer certain advantages, Service Max J1939-J1708’s tailored design for heavy-duty applications ensures it remains a critical component in the vehicle diagnostics landscape.

Common Applications of Service Max J1939-J1708

The versatility of Service Max J1939-J1708 allows it to be utilized across various applications in the automotive and transportation industries. Understanding these applications showcases the protocol’s value and relevance.

Fleet Management

One of the primary applications of Service Max J1939-J1708 is in fleet management systems. Businesses operating fleets of heavy-duty vehicles rely on this protocol to implement real-time monitoring and diagnostics.

Fleet operators can track vehicle performance metrics, such as fuel consumption and engine health, to maximize efficiency. Access to real-time data empowers fleet managers to make informed decisions on route optimization, maintenance scheduling, and resource allocation—all key factors in minimizing operational costs.

Engine Diagnostics

Service Max J1939-J1708 excels in engine diagnostics, providing detailed insights into engine performance and health. By utilizing the diagnostic capabilities offered by this protocol, technicians can quickly identify and address issues affecting engine operation.

Access to DTCs enables mechanics to perform targeted repairs rather than resorting to trial-and-error approaches. Furthermore, continuous monitoring of engine parameters allows for proactive maintenance, ensuring that engines operate optimally and comply with emissions regulations.

Fuel Management Systems

Fuel management is another area where Service Max J1939-J1708 proves invaluable. The protocol’s ability to monitor fuel consumption and identify inefficiencies is crucial in today’s economy, where fuel costs represent a significant portion of operational expenses.

Fleet operators can leverage data retrieved through Service Max to optimize fuel usage, implement best practices, and train drivers on efficient driving habits. This optimization leads to reduced waste and improved overall fuel economy.

Emissions Monitoring

As environmental regulations tighten, the need for effective emissions monitoring continues to grow. Service Max J1939-J1708 supports compliance efforts by facilitating detailed emissions diagnostics.

By accessing data related to exhaust after-treatment systems, operators can monitor the performance of components such as diesel particulate filters (DPF) and selective catalytic reduction (SCR) systems. Ensuring these systems operate correctly is essential for meeting regulatory standards and reducing environmental impact.

Troubleshooting Service Max J1939-J1708 Issues

Like any technological system, issues may arise when using Service Max J1939-J1708. Knowing how to troubleshoot these problems is crucial for maintaining efficient vehicle operations.

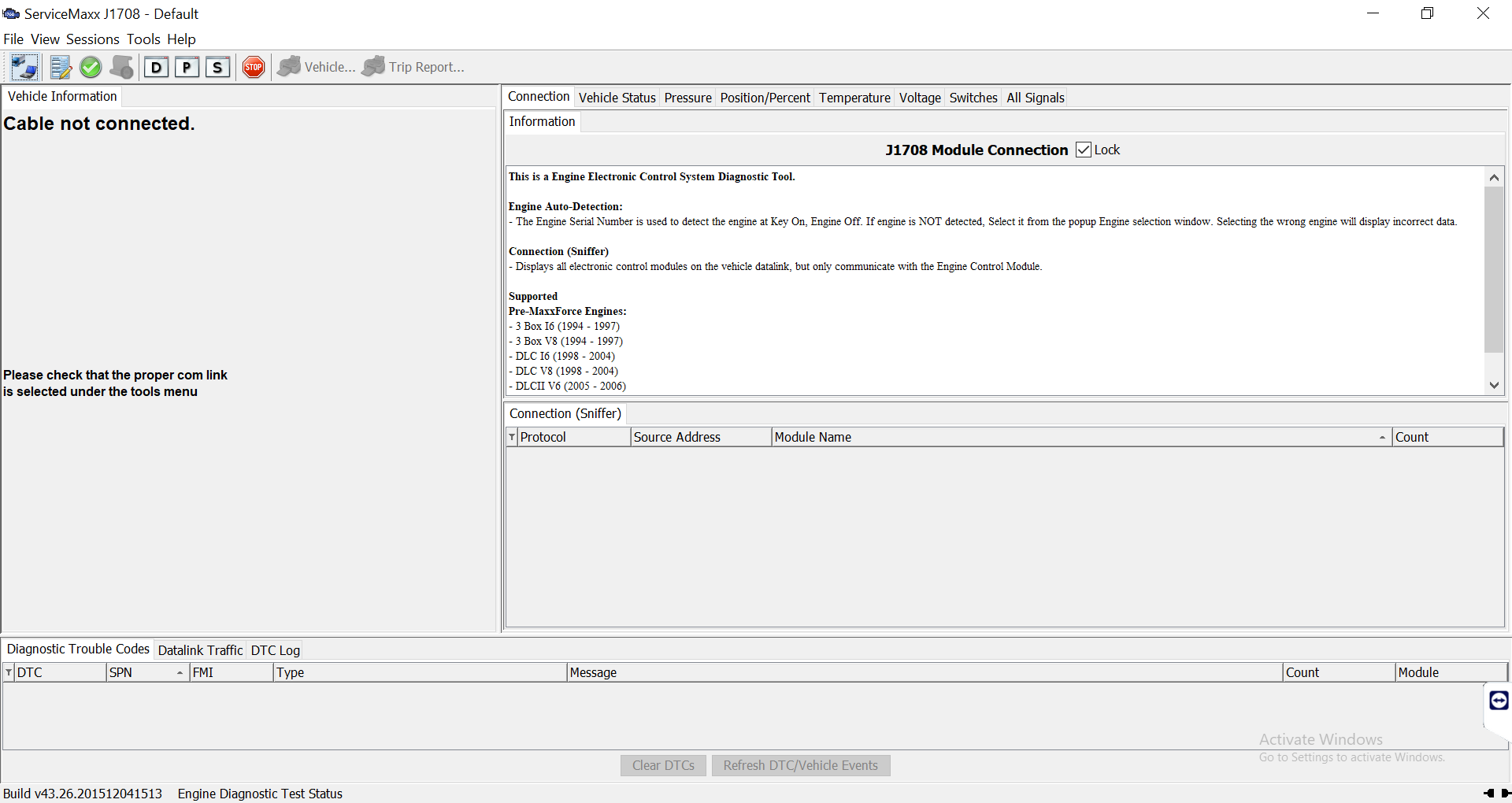

Identifying Connection Issues

A common challenge technicians may encounter is connectivity problems between the diagnostic tool and the vehicle’s ECUs. This could stem from faulty connections, incompatible cables, or issues within the vehicle’s wiring harness.

To troubleshoot, begin by verifying physical connections and ensuring the diagnostic tool is properly configured. If connections seem intact, checking for electrical continuity in the wiring harness can help uncover hidden issues. Moreover, ensuring that the correct protocols are selected within the diagnostic software is vital.

Diagnosing Communication Failures

Communication failures could manifest as missing or incomplete data from the ECUs. Effective troubleshooting involves checking the communication settings for any discrepancies between the vehicle and diagnostic tool configurations.

Utilizing a CAN bus analyzer can pinpoint message transmission errors or conflicts. Additionally, inspecting the data format for consistency with the expected J1939/J1708 specifications can help in identifying potential misconfigurations.

Managing Fault Codes

When encountering DTCs, technicians should follow a systematic approach to address the underlying problems. First, retrieving the DTCs using the Service Max diagnostic tool will provide insights into what systems require attention.

Each DTC comes with a description that can guide technicians toward the probable causes of the issue. Performing visual inspections and testing individual components based on the DTC descriptions will facilitate targeted repairs, minimizing downtime and maximizing efficiency.

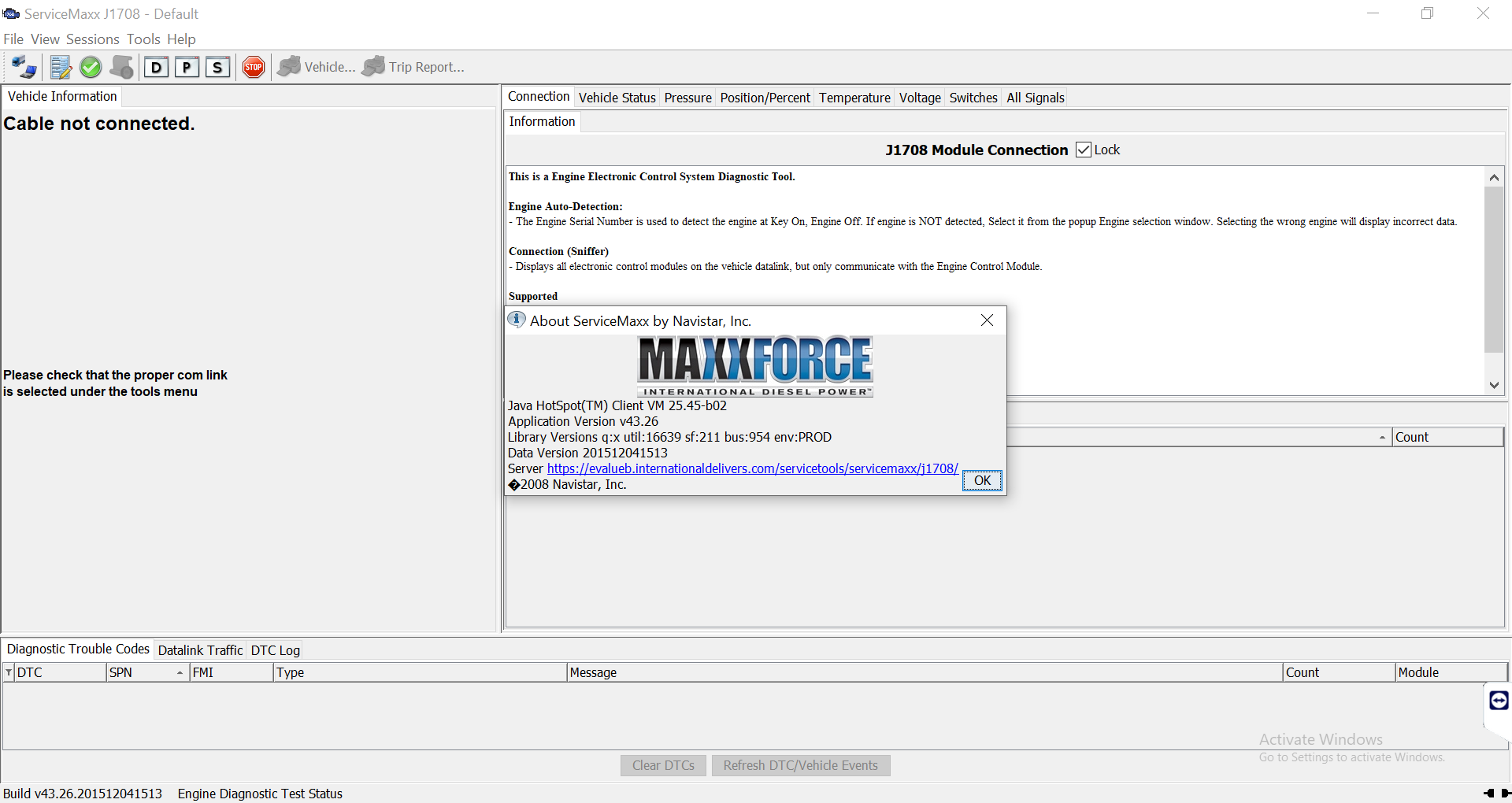

Updating Software and Firmware

Software and firmware updates play a pivotal role in ensuring the smooth operation of Service Max J1939-J1708. Failure to keep diagnostic tools and vehicle ECUs updated can lead to compatibility issues and hinder performance.

Regularly checking for updates from manufacturers and applying them as needed is crucial for avoiding potential pitfalls. Following the manufacturer’s instructions for software updates will aid in maintaining optimal functionality.

Installation Guide for Service Max J1939-J1708

Installing Service Max J1939-J1708 can be achieved with relative ease if proper steps are followed. Here’s a comprehensive guide to assist technicians and fleet managers in the installation process.

Pre-installation Preparation

Before diving into the installation, it’s essential to gather all necessary tools and materials. This may include a compatible diagnostic tool, cables, and appropriate software.

Ensure that the vehicle’s battery is disconnected to avoid potential electrical issues during the installation process. Reviewing the manufacturer’s guidelines for specific vehicle models can provide additional insight into any unique requirements.

Connecting Diagnostic Tools

To begin the installation, connect the diagnostic tool to the vehicle’s OBD-II port or equivalent connector that interfaces with the ECUs. This can usually be found beneath the dashboard near the driver’s seat.

Once the connection is secure, power on the diagnostic tool and follow the prompts to establish communication with the vehicle. Be sure to verify that the correct protocol (Service Max J1939-J1708) is selected within the tool’s settings.

Configuring Software Settings

After establishing a connection, launch the associated software that supports Service Max J1939-J1708. Ensure that all software components are updated to the latest versions to guarantee compatibility and access to new features.

Configuring the software settings may involve selecting the vehicle make and model, ensuring that the diagnostic tool recognizes the appropriate parameters for communication. Always refer to the user manual for guidance on configuration options.

Testing Functionality

Upon completing the installation and configuration, it’s time to test the functionality. Conduct a series of diagnostic tests to confirm that the tool can successfully retrieve data from the ECUs.

Monitor for any error messages or communication issues. If everything operates smoothly, begin utilizing Service Max J1939-J1708 for ongoing vehicle diagnostics and maintenance.

Real-World Case Studies of Service Max J1939-J1708

To better illustrate the practical applications and advantages of Service Max J1939-J1708, we can examine several real-world case studies showcasing its effectiveness in various scenarios.

Fleet Optimization in a Delivery Company

A regional delivery company operating a fleet of medium-duty trucks faced challenges with vehicle breakdowns that resulted in significant delays and increased costs. They decided to implement Service Max J1939-J1708 to enhance their fleet management capabilities.

Through the use of Service Max, the company was able to conduct real-time diagnostics, identify recurring engine issues, and develop proactive maintenance schedules based on actual vehicle performance data. This led to a notable reduction in unplanned downtimes and improved delivery timelines.

Furthermore, the ability to monitor fuel consumption across the entire fleet allowed the company to implement driver training programs focused on fuel-efficient driving practices. As a result, overall fuel expenditures decreased by a considerable margin.

Improving Diagnostics in a Construction Firm

A construction firm that relied heavily on heavy machinery encountered persistent issues with diagnostic accuracy when servicing their equipment. They introduced Service Max J1939-J1708 as part of their maintenance strategy to improve their diagnostic processes.

With Service Max, mechanics gained access to comprehensive DTCs and real-time performance data, allowing them to address issues swiftly. Technicians reported a marked improvement in their ability to resolve problems, resulting in fewer instances of equipment breakdowns on-site.

Additionally, Service Max’s user-friendly interface facilitated training for new employees, enabling them to become proficient in diagnostics much quicker than with previous systems. This enhancement in workforce capability translated into increased productivity on job sites.

Emission Compliance in a Municipal Fleet

A municipal fleet responsible for public transport and sanitation services faced mounting pressure to comply with stringent emissions regulations. To address these concerns, they sought to adopt Service Max J1939-J1708 to improve their emissions monitoring practices.

Using Service Max, the fleet could continuously monitor emissions-related parameters from their vehicles’ ECUs. This vigilance allowed them to identify malfunctioning components in the exhaust after-treatment systems quickly.

By implementing a preventive maintenance program guided by the insights gained from Service Max, the municipal fleet successfully met regulatory requirements, avoiding costly fines and reinforcing their commitment to sustainability.

Future Developments in Service Max J1939-J1708

As technology continues to evolve, so too does the realm of vehicle diagnostics. Looking ahead, several developments are poised to shape the future of Service Max J1939-J1708.

Integration with Advanced Technologies

Future iterations of Service Max J1939-J1708 may see deeper integration with advanced technologies such as artificial intelligence (AI) and machine learning. By analyzing historical data and learning from past behaviors, these technologies could predict potential failures with even greater accuracy.

The incorporation of AI could also enhance diagnostic capabilities by automating troubleshooting processes, further simplifying the workload for technicians and enabling them to focus on higher-level repairs.

Expansion into Electric Vehicles

As electric vehicles (EVs) gain traction in the market, the adaptation of Service Max to support EV diagnostics will be critical. While J1939-J1708 currently serves internal combustion engine systems, expanding its functionality to encompass electric drivetrains presents an opportunity for growth.

Developing protocols that cater specifically to the unique requirements of EV diagnostics will ensure that Service Max remains relevant within the evolving automotive landscape.

Enhanced Cybersecurity Measures

With increasing reliance on connected vehicles and data sharing, cybersecurity will become an essential consideration for Service Max J1939-J1708. As threats to vehicle systems evolve, robust security frameworks must be implemented to safeguard against unauthorized access and manipulation.

Future versions of Service Max may incorporate advanced encryption standards and intrusion detection systems to protect sensitive data and maintain the integrity of vehicle communications.

Sustainability Initiatives

Finally, the push for sustainability across industries will undoubtedly influence the development of Service Max J1939-J1708. By streamlining diagnostics and promoting efficient resource utilization, Service Max can play a pivotal role in supporting environmentally friendly practices within the automotive sector.

Focus on emissions reduction, energy efficiency, and overall sustainable practices will likely shape the direction of future developments in Service Max, aligning it with global initiatives for a greener future.

Conclusion

In conclusion, Service Max J1939-J1708 stands at the forefront of innovation in the realm of vehicle diagnostics and communication. Its integration of J1939 and J1708 protocols offers unparalleled benefits, including comprehensive diagnostics, enhanced data transmission, compatibility, and user-friendly interfaces.

Fleet managers, technicians, and automotive professionals can capitalize on its capabilities to drive operational efficiency, reduce costs, enhance safety, and ensure compliance with industry standards. The forward-looking developments poised for Service Max signal its sustained relevance amid rapid technological advancements.

As the automotive industry continues to evolve, embracing protocols like Service Max J1939-J1708 will prove essential for anyone seeking to navigate the complexities of modern vehicle management successfully.

📥 Contact Us:

🌐 Website: www.diagtechpro.com

📲 WhatsApp: https://wa.me/message/K6JOQMVFBGSAD1

📧 Email: di4gtechpro@gmail.com

Be the first to review “Service Max J1939-J1708” Cancel reply

Related products

All Product

All Product

All Product

All Product

Reviews

There are no reviews yet.