Cummins Calterm Version 5.16 – Advanced ECM Control and Precision Tuning for Cummins Engines

126 $ Original price was: 126 $.105 $Current price is: 105 $.

Brand: CUMMINS CALTERM

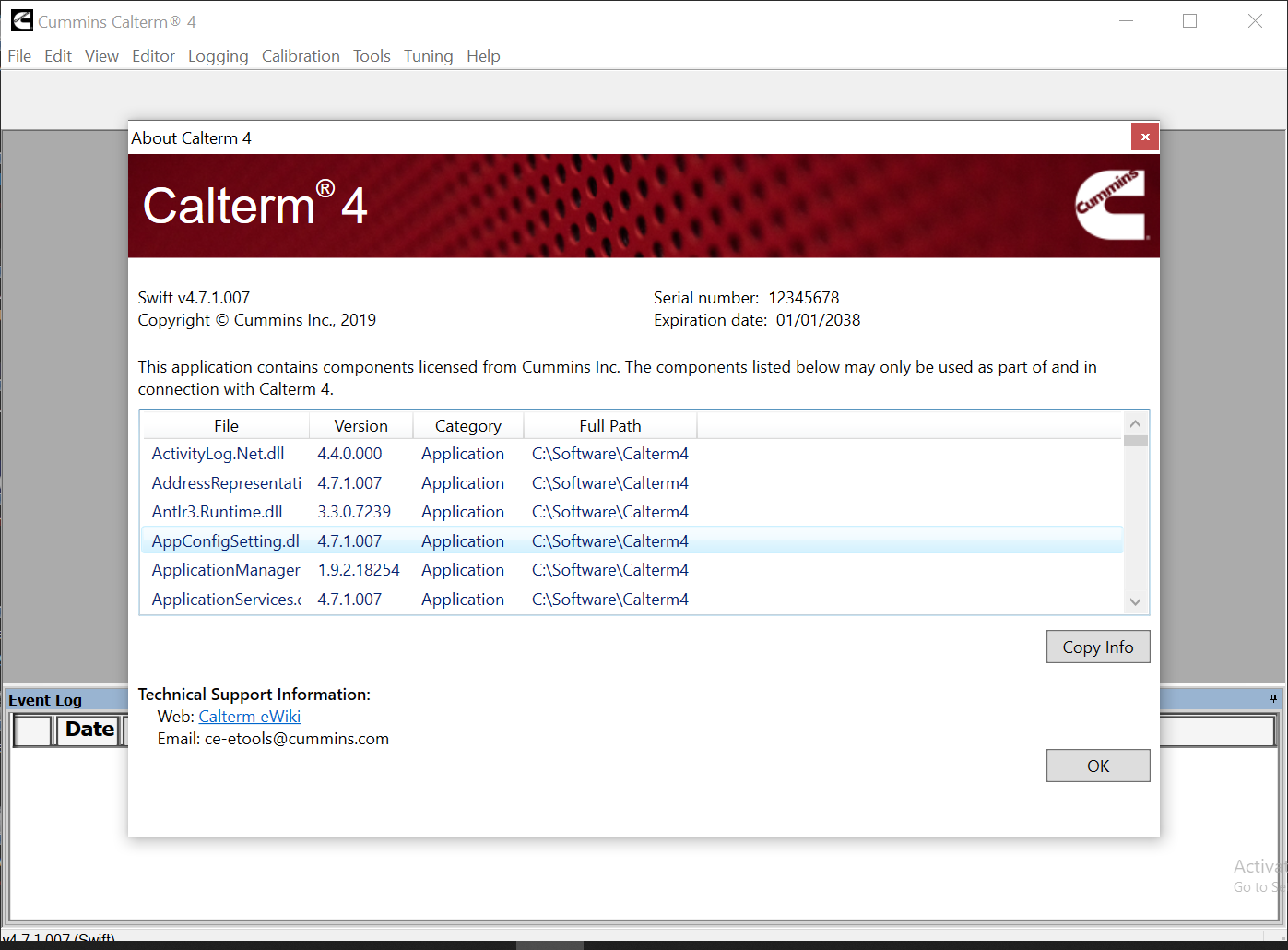

Version: V4.7 +V5.16

File Size: 173.2 MB

License Time: 2 year

Software Type: Windows-based application for engine calibration and diagnostics

Region: Global

OS Support: Windows 10, 11

Category: All Product

Size Installed: 500 MB

Database Language: English

Interface Language: English

Cummins Calterm is a powerful engineering-level software tool used to monitor, modify, and test Cummins ECMs (Engine Control Modules). Developed for advanced users such as engineers, fleet calibration specialists, and diesel tuning professionals, it offers low-level access to ECM functionality not available through standard tools like Cummins INSITE. With its sophisticated features, Cummins Calterm stands out as an essential tool for those seeking advanced ECM control and tuning capabilities.

What is Cummins Calterm?

ummins Calterm serves as a premier software solution designed specifically for managing electronic control units in Cummins engines. It allows professional users to delve deep into the intricacies of engine management systems, facilitating a level of control that surpasses conventional diagnostic applications.

The architecture of Cummins Calterm is built upon years of expertise in engine development and performance. The software is tailored for an audience that requires precision and fine-tuning capabilities. Whether you are an engineer looking to optimize engine performance or a technician needing to troubleshoot complex issues, Cummins Calterm can empower your work with its extensive functionality.

In essence, it enables users to modify parameters within the ECM to improve overall engine efficiency, performance, and diagnostics. This capability is crucial as engines become more intricate, featuring numerous sensors and controls that interact in sophisticated ways. By utilizing Calterm, professionals gain insights that aid in understanding these interactions, leading to informed decisions during repairs, upgrades, or performance enhancements.

To support industry professionals, diagtechpro.com provides Cummins Calterm in both version 4.7 and the latest 5.16, ensuring users have access to the right tools for their specific needs.

The Evolution of Engine Control Technology

Understanding the evolution of engine control technology is vital to appreciating the prowess of Cummins Calterm. Over the years, engine management systems have transitioned from basic mechanical setups to highly sophisticated electronic frameworks. Traditional engines relied on mechanical linkages and carburetors, while modern engines depend heavily on intricate ECMs that manage fuel injection, ignition timing, emissions controls, and more.

This transition has necessitated advanced tools capable of navigating the complexities of ECM tuning. Cummins Calterm answers this need by offering a user-friendly interface combined with robust functionalities that put significant control back into the hands of knowledgeable users.

As the automotive industry moves toward greener technologies, including electric and hybrid vehicles, the role of software in achieving optimal performance continues to expand. Calterm not only prepares users for today’s challenges but also equips them with tools adaptable to future advancements in engine technology.

Target Audience for Cummins Calterm

The primary users of Cummins Calterm are professionals who operate at the cutting edge of engine technology. This includes engineers engaged in product development, performance enhancement specialists in the aftermarket, and fleet managers focused on efficiency. Each group leverages the unique capabilities of Calterm based on their specific needs and objectives.

For engineers developing new engine models, real-time data analysis and parameter manipulation can vastly improve the design process. Performance specialists can utilize Calterm to tune engines for maximum output or fuel efficiency. Fleet managers benefit from the ability to customize individual settings across multiple engines, optimizing performance according to operational demands.

In summary, Cummins Calterm is designed for anyone involved in the intricate world of Cummins engine management, serving as a bridge between theoretical knowledge and practical application. Its depth and breadth make it indispensable for achieving peak engine performance.

Key Functions of Cummins Calterm

Cummins Calterm boasts a plethora of critical functions that cater to the diverse needs of engine tuning and management. This section will explore some of the most prominent features of the software, emphasizing how each contributes to enhanced engine control and optimization.

ECM Parameter Modification

At the heart of Cummins Calterm lies its ability to modify ECM parameters, allowing users to adjust various settings for optimal performance. The software provides access to both protected and unprotected parameters, enabling customizations that would otherwise remain locked in standard diagnostic tools.

Users can enable or disable specific functions, such as Exhaust Gas Recirculation (EGR) and Diesel Particulate Filters (DPF). These adjustments offer potential performance improvements but require a deep understanding of the engine’s operating conditions. For example, disabling EGR might yield greater power outputs but could lead to increased emissions if not managed properly.

Moreover, the customization capabilities extend far beyond simple toggle switches. Advanced users can manipulate fuel maps, ignition timing, and boost pressures, creating tailored configurations suited for unique operating environments. Engaging in such detailed tuning empowers users to tap into the full potential of their Cummins engines, translating to palpable gains in performance and efficiency.

Real-Time Monitoring & Data Logging

Another hallmark feature of Cummins Calterm is its real-time monitoring and data logging capabilities. This function is invaluable for both diagnostics and performance evaluation. Engine sensor data can be viewed live, providing immediate feedback on engine behavior under different conditions.

Data logging allows users to record engine parameters over time, which can be analyzed later for trends and anomalies. This is particularly useful when testing under load, where understanding how the engine performs in real-world scenarios becomes essential. Gathering comprehensive datasets helps identify potential issues that may not be apparent during routine inspections.

Additionally, real-time data monitoring is crucial for calibrating new modifications. When changes are made to parameters, observing the immediate effects on engine performance ensures that adjustments yield the desired outcomes without introducing instability or reliability concerns.

Calibration and Flashing

Calibration and flashing are core functions within Cummins Calterm that allow users to update the ECM’s software. By flashing custom or original equipment manufacturer (OEM) calibrations into the ECM, users can ensure their engines run optimally with the latest software revisions.

The software supports password-protected or locked ECMs, enabling users to navigate security measures when necessary. Proper access levels are essential for executing these tasks effectively, as they prevent unauthorized modifications that could lead to detrimental outcomes.

One of the more controversial aspects of using Cummins Calterm involves emissions deletes, such as removing DPF, EGR, and DEF systems for off-road use only. While there are legitimate reasons for doing so—such as improving performance in specific applications—users must proceed with caution. Understanding local regulations surrounding emissions is integral to responsible engine management.

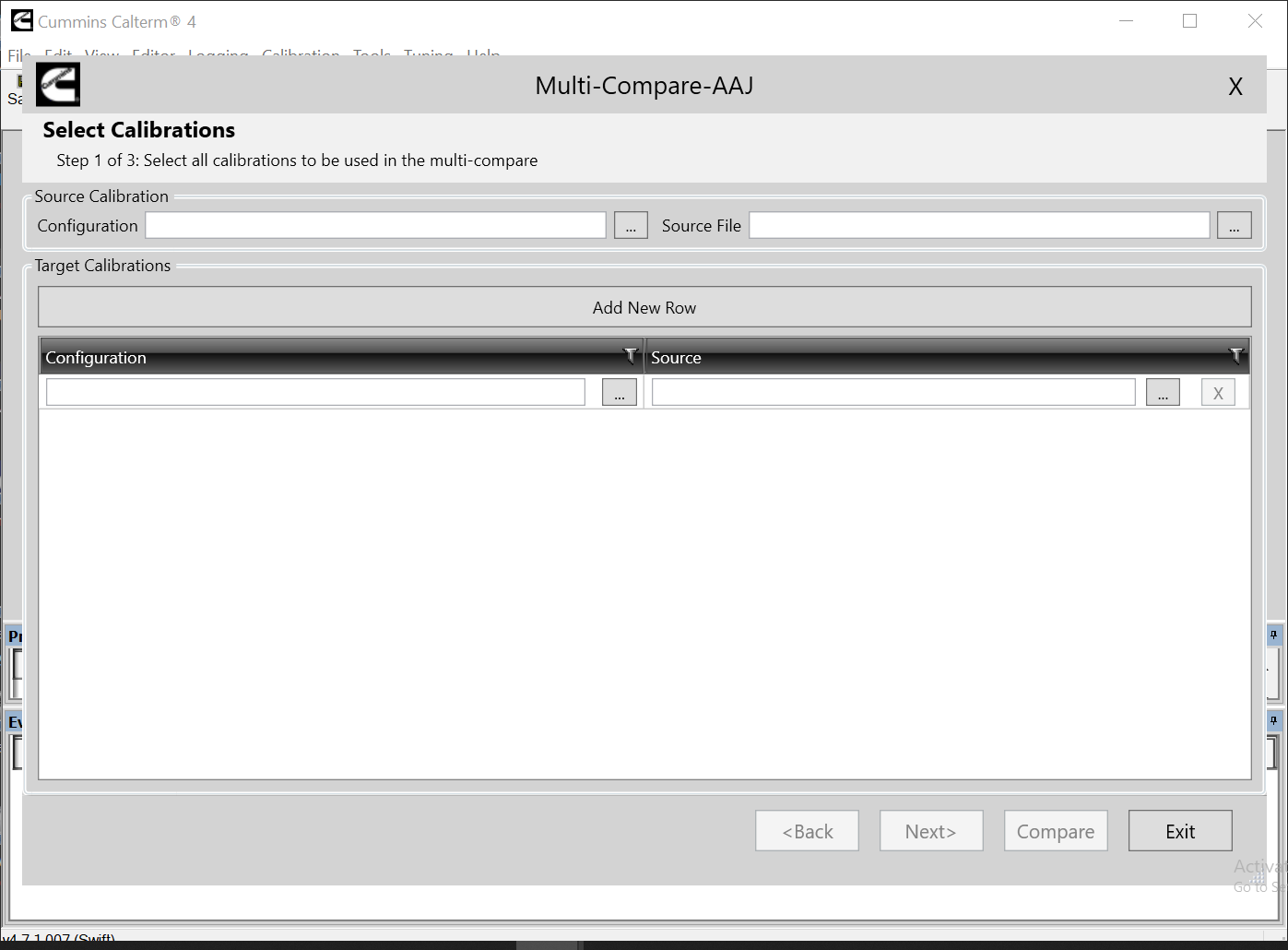

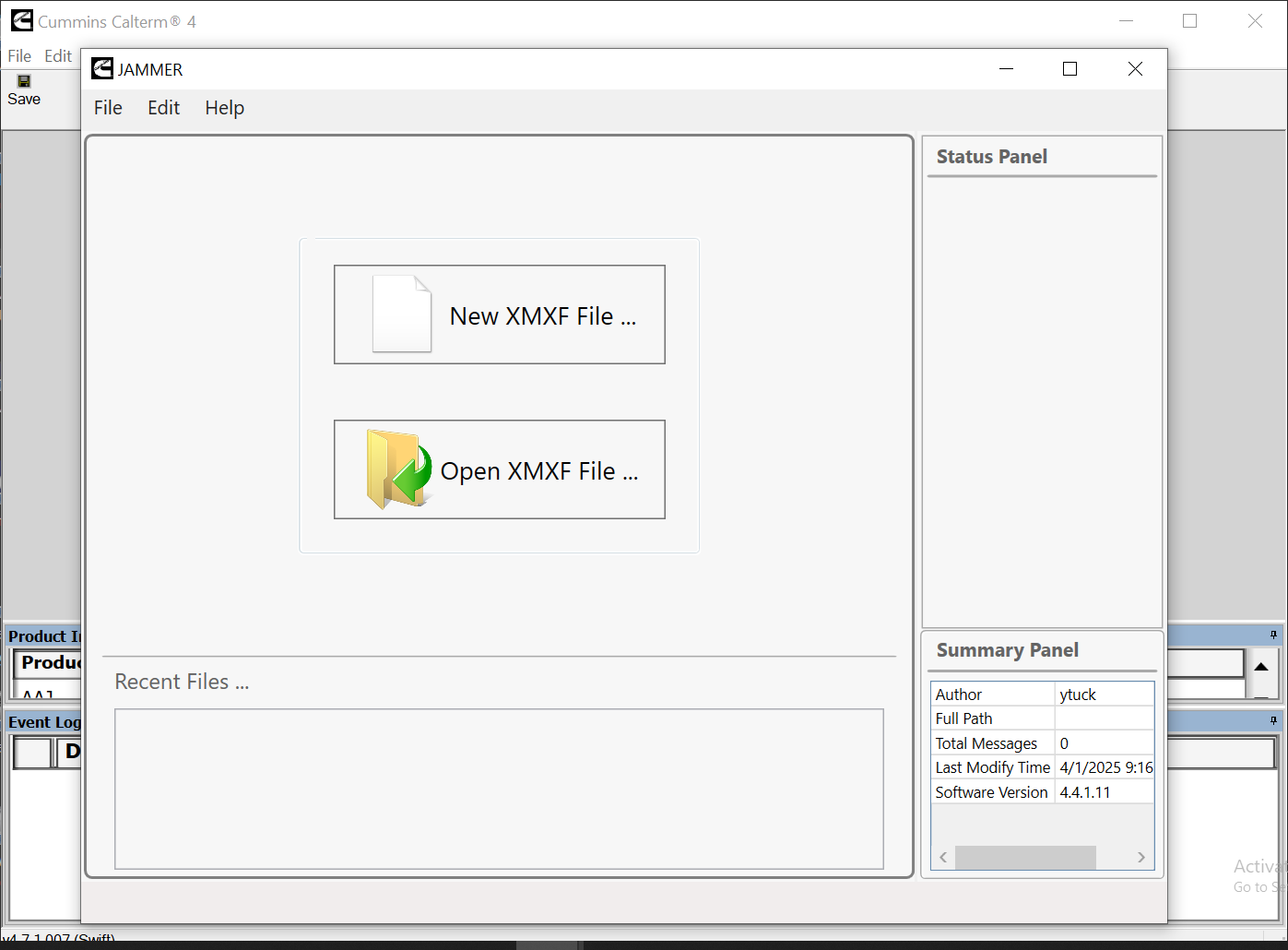

Script-Based Automation & Testing

Cummins Calterm incorporates a script-based automation feature that sets it apart from many other tuning tools. This allows users to run pre-defined diagnostic routines, test cycles, or even automate entire calibration processes, making it especially useful for OEMs and advanced fleet operations.

Running automated tests can significantly streamline workflows, helping technicians accomplish complex tasks without extensive manual intervention. This automation fosters consistency and repeatability, ensuring that the same high-quality standards are maintained across all evaluations.

Moreover, the ability to script custom actions opens doors for innovative testing methodologies. Users can craft unique scripts tailored to specific needs, pushing the boundaries of traditional testing paradigms. This flexibility positions Cummins Calterm as a pivotal resource in advancing engine technology.

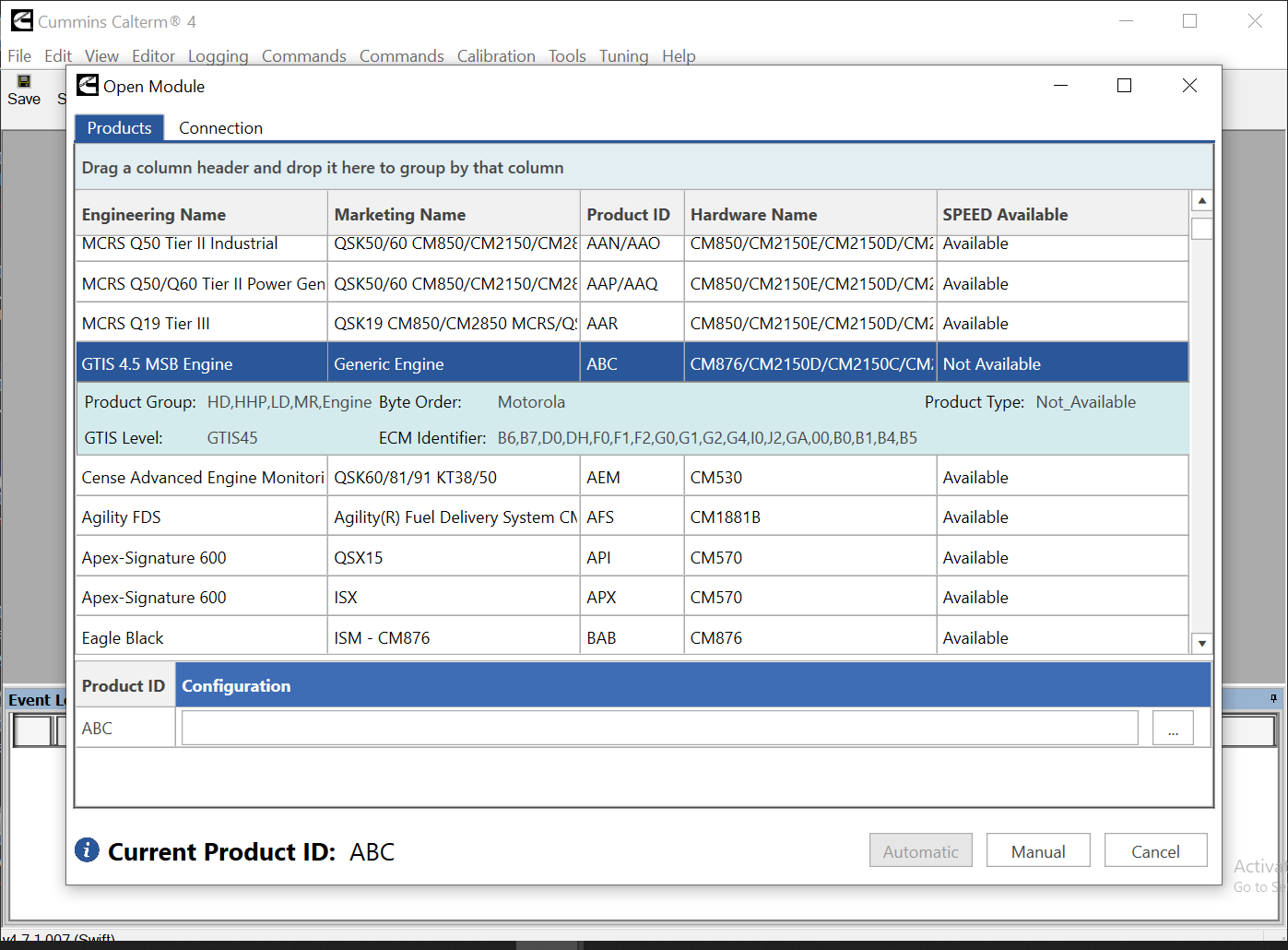

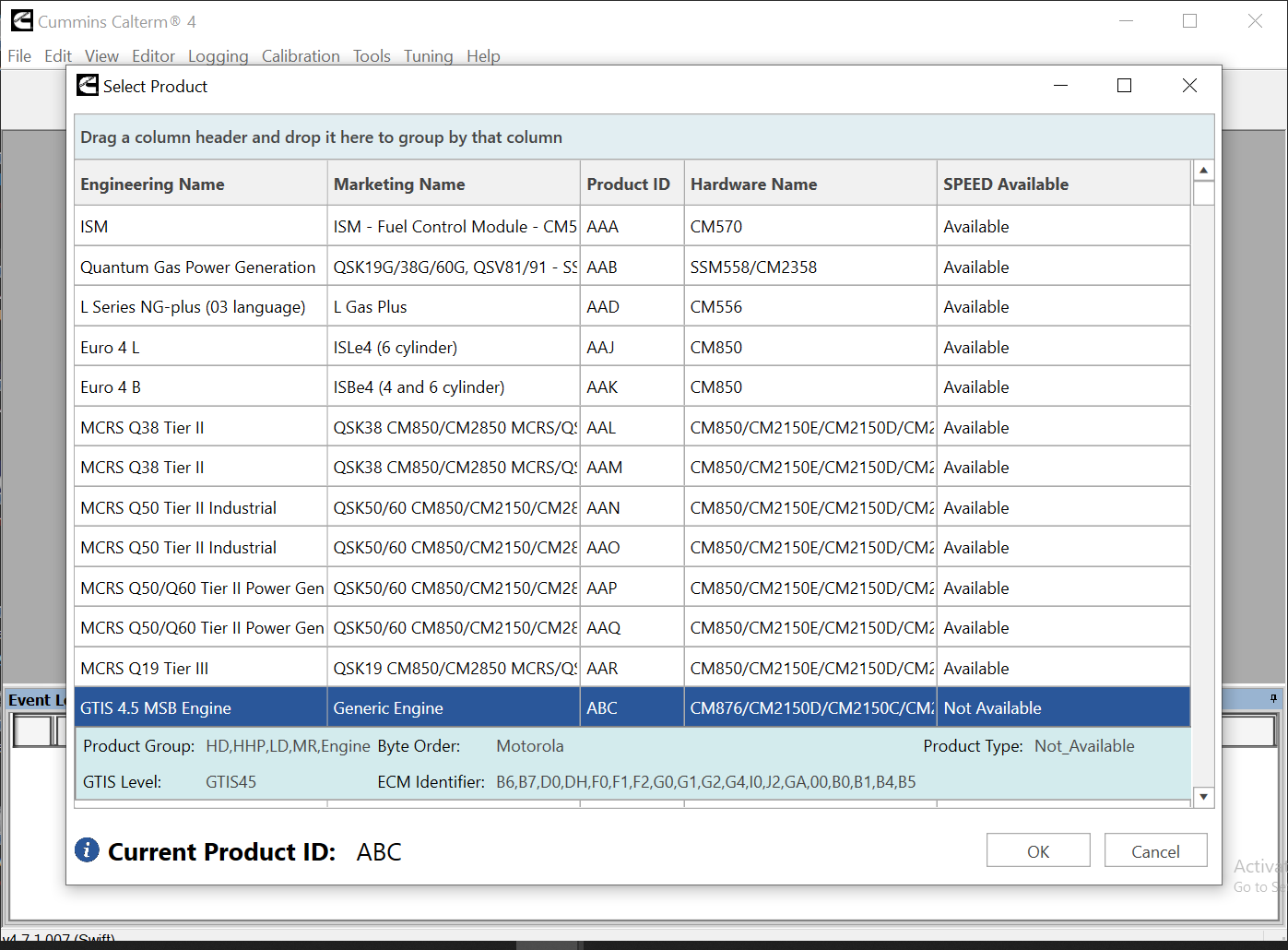

Supported ECM Types

A defining characteristic of Cummins Calterm is its broad compatibility with various ECM types. This versatility makes it a go-to solution for professionals working with a range of Cummins engines across different sectors, including on-highway, off-highway, industrial, and marine applications.

On-Highway Applications

In the realm of on-highway vehicles, Cummins engines power an array of heavy-duty trucks and commercial vehicles. As emissions regulations continue to tighten, the need for effective tuning solutions becomes increasingly paramount.

Cummins Calterm allows fleet owners and operators to optimize their engine settings for improved fuel economy, reduced emissions, and enhanced performance. These capabilities translate directly into cost savings and operational efficiencies, both of which are critical in a competitive industry.

Off-Highway Applications

Off-highway applications encompass a wide variety of machinery utilized in construction, agriculture, mining, and other industries. Here, Cummins engines often operate under demanding conditions, requiring precise calibration for peak performance.

In these scenarios, the ability to fine-tune engine parameters can mean the difference between efficient operation and costly downtime. Cummins Calterm enables users to adapt their engines to the unique demands of specific jobs, improving productivity and return on investment.

Industrial and Marine Engines

Cummins engines also find extensive use in industrial and marine settings, where reliability and efficiency are non-negotiable. For operators in these segments, Cummins Calterm provides the tools to tailor engine performance for specific applications, whether it’s powering generators, tugboats, or any specialized machinery.

With applications in diverse fields, having a software solution that can handle various ECM configurations is crucial. Cummins Calterm’s support for multiple ECM types solidifies its position as an essential asset for engineers and technicians alike.

Calterm vs. Cummins INSITE

When comparing Cummins Calterm to another popular tool, Cummins INSITE, several key differences emerge. Both software packages serve important functions, but they cater to varying user needs and operational requirements.

Feature Set

While Cummins INSITE offers comprehensive diagnostic capabilities and basic tuning options, Calterm elevates the experience by providing deeper access to ECM parameters and sophisticated tuning functionalities. For users looking to push the boundaries of engine performance and customization, Calterm is the superior choice.

User Level

Cummins INSITE is designed primarily for general technicians and service personnel, making it more user-friendly for those who may lack extensive technical training. In contrast, Cummins Calterm targets advanced users, including engineers and tuning specialists who possess a thorough understanding of engine dynamics.

This distinction means that while INSITE is excellent for everyday maintenance and troubleshooting, Calterm is the tool of choice for serious performance-enhancing endeavors.

ECM Access

One of the most notable differences lies in the level of ECM access provided by each tool. Calterm grants low-level access to a broader set of ECM functions, allowing for profound modifications that INSITE does not facilitate. This access empowers users to enact changes that can significantly impact engine performance.

Calibration Capabilities

Calterm takes calibration to the next level. While both tools can perform basic flashing and calibration, Calterm supports a wider array of custom calibrations and advanced scripting options. This flexibility positions Calterm as an ideal solution for those committed to maximizing engine potential, particularly in racing or specialized applications.

Note: Emission deletes are illegal on public roads in many regions and are only for off-highway or race use.

Required Tools and Setup

To leverage the capabilities of Cummins Calterm effectively, users must ensure they have the proper tools and setup in place. This section outlines the essential components required to get started with the software.

Laptop Configuration

Firstly, users need a compatible laptop, preferably running on a 64-bit version of Windows OS, typically Windows 10 or 11. A robust system is recommended to handle the processing demands of Cummins Calterm efficiently. Given the complexity of engine data analysis, investing in a machine with adequate processing power and memory will enhance the user experience.

Interface Device

Secondly, an interface device is crucial for establishing communication between the laptop and the ECM. Devices such as the Cummins Inline 6 or 7 and Nexiq USB Link (which adheres to RP1210 protocols) are widely recognized for their reliability and compatibility with Cummins engines. Ensure that the chosen interface device supports the particular ECMs being worked on for seamless integration.

Software License and Security Credentials

Lastly, operating Cummins Calterm requires obtaining a valid software license. This licensing agreement allows users to unlock the full potential of the tool and receive regular updates. Additionally, security credentials are needed to access password-protected or locked ECMs. Credentials may include password unlock codes or Zap-It keys, depending on the ECM configuration.

By assembling these components, users can embark on their journey into the advanced realm of ECM control and tuning with confidence.

Who Uses Cummins Calterm?

Cummins Calterm serves as an essential tool for a variety of professionals engaged in the management and tuning of Cummins engines. This section delves into the different user groups that benefit from the software’s advanced capabilities.

ECM Tuning Professionals and Diesel Performance Shops

For professionals specializing in engine tuning, Cummins Calterm represents a cornerstone of their toolkit. These experts utilize its extensive feature set to maximize engine performance, gain competitive advantages, and deliver tailored solutions for their clients.

Diesel performance shops often cater to enthusiasts and businesses seeking heightened power outputs or customized setups. By leveraging Calterm, these shops can provide sophisticated tuning solutions that meet customer expectations while adhering to compliance standards.

Fleet Calibration Teams

Fleet calibration teams play a vital role in ensuring that all engines within a fleet operate efficiently and reliably. Cummins Calterm allows these teams to create consistent calibration profiles across multiple vehicles, optimizing fuel consumption and reducing operational costs.

When managing a large fleet, standardization becomes key. Calterm facilitates the implementation of uniform settings across similar engine types, preventing variability in performance that could lead to inefficiencies.

OEMs and Engine Builders

Original Equipment Manufacturers (OEMs) and engine builders are increasingly turning to advanced tools like Cummins Calterm during the product development phase. Having access to low-level ECM functions allows these entities to conduct rigorous testing and validation of new engine designs.

By employing the advanced capabilities of Calterm, engineers can assess parameters that may affect engine durability, performance, and compliance with emissions standards. This kind of thorough testing ultimately results in better-engineered products that satisfy market demands.

Advanced Repair Shops

Advanced repair shops specializing in electronic engine diagnostics also harness the power of Cummins Calterm. Equipped with the right tools, these shops can tackle complex issues that arise from modern engine management systems.

With the ability to monitor, diagnose, and calibrate engines accurately, repair technicians can address problems more swiftly, minimizing downtime for customers. Employing Calterm significantly enhances the shop’s reputation for quality service and technical expertise.

Risks and Legal Notes

While Cummins Calterm offers unparalleled opportunities for ECM tuning and control, it is imperative to approach its use with caution. This section outlines potential risks and highlights the importance of complying with applicable laws and regulations.

Improper Use Consequences

One of the greatest risks associated with using advanced tuning software is the potential for damaging ECMs or voiding warranties. Inexperienced users may inadvertently alter critical parameters that disrupt engine functionality or compromise reliability. Such mistakes can lead to costly repairs and operational disruptions.

It is crucial for users to have a comprehensive understanding of the systems they are modifying. Knowledgeable professionals should always double-check settings before applying any changes to minimize the risk of unintended consequences.

Compliance with Emissions Laws

Cummins Calterm can facilitate emissions deletes, such as disabling DPF or EGR systems. However, users must understand the legal implications of such actions. Modifying an engine to circumvent emissions regulations is illegal in many jurisdictions and can result in severe penalties.

Operators should ensure they are well-informed about their local regulations before proceeding with any emissions-related modifications. This awareness not only protects against legal repercussions but also promotes ethical practices in the industry.

Trained and Qualified Professionals Only

Given the complexities involved in engine tuning, Cummins Calterm is only recommended for trained and qualified professionals. Possessing the necessary expertise ensures that users can fully exploit the software’s capabilities while mitigating risks associated with improper alterations.

Organizations should invest in training programs for employees or collaborate with experienced professionals when venturing into advanced tuning. This commitment to education and skill development pays dividends in the long run, fostering a culture of safety and excellence.

Conclusion – The Power of Full ECM Control

In conclusion, Cummins Calterm stands as an unmatched tool in the landscape of ECM control and calibration. Its advanced functionalities empower users to dive deep into the intricacies of Cummins engines, unlocking capabilities that go beyond standard diagnostic software.

From parameter modification to real-time monitoring, calibration flashing, and script-based testing, Calterm equips professionals with everything they need to achieve peak engine performance. Furthermore, its compatibility with a wide variety of ECM types ensures that it remains relevant across various applications.

As users navigate the possibilities presented by Cummins Calterm, they must remain mindful of the responsibilities that accompany such powerful tools. Approaching engine tuning with respect for regulatory compliance and a commitment to best practices will pave the way for sustainable advancements in engine technology.

Ultimately, Cummins Calterm is not just a software tool; it represents a gateway to unlocking the full potential of Cummins engines, driving innovation and performance enhancements across the industry. With conscientious usage, professionals can harness its capabilities to redefine what is possible in the realm of engine management.

📥 Contact Us:

🌐 Website: www.diagtechpro.com

📲 WhatsApp: https://wa.me/message/K6JOQMVFBGSAD1

📧 Email: di4gtechpro@gmail.com

| Version | 3.17, 4.7, 5.16 |

|---|

Be the first to review “Cummins Calterm Version 5.16 – Advanced ECM Control and Precision Tuning for Cummins Engines” Cancel reply

Related products

All Product

All Product

Cummins CalFix for INSITE – Powerful Engine Calibration and Fault Fixing for Cummins Engines

All Product

All Product

Reviews

There are no reviews yet.