Cummins CalFix for INSITE – Powerful Engine Calibration and Fault Fixing for Cummins Engines

126 $ Original price was: 126 $.105 $Current price is: 105 $.

Brand: CUMMINS CALFIX FOR INSITE

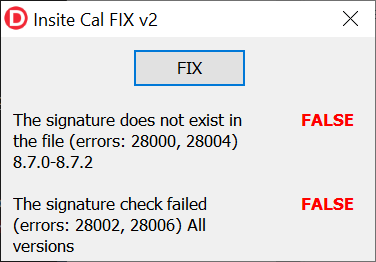

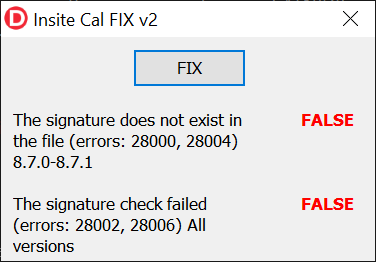

Version: CalFix v2

File Size: 20 MB

License Time: 2 year

Software Type: Third-party Windows-based calibration editing tool

Region: Global

OS Support: Windows 10,11

Category: All Product

Size Installed: 20 MB

Database Language: English

Interface Language: English

Cummins CalFix for INSITE is an advanced software tool specifically designed to work alongside Cummins INSITE. This powerful engine calibration and fault-fixing tool caters to the intricate needs of Cummins engines, enabling technicians to make precise adjustments, resolve faults, and enhance performance in a way that standard diagnostic tools simply cannot achieve. By allowing users to directly modify settings in the engine control module (ECM), it empowers professionals to optimize their engines like never before.

What is Cummins CalFix for INSITE?

Cummins CalFix for INSITE is not just another piece of software; it’s a sophisticated tool tailored for those who demand precision in engine diagnostics and repairs. Built as an extension of the well-known Cummins INSITE software, CalFix allows for advanced calibration fixes that are essential for modern diesel engines.

This specialized tool has been created with the understanding that some engine-related issues require more than just surface-level diagnostics. Many times, technicians encounter problems that can only be resolved through modifications made directly to the ECM. As such, Cummins CalFix becomes invaluable, particularly when standard diagnostic tools fall short.

Advanced Software Tool

The software operates as an integrated platform designed for use by trained technicians who possess a deep understanding of engine mechanics. Cummins CalFix provides access to advanced features that enable users to adjust critical engine parameters in real time, enhancing overall engine performance. With its user-friendly interface, technicians can navigate through complex data effortlessly, allowing them to make informed decisions while working on a diverse range of Cummins engines.

Furthermore, the ability to implement calibration changes helps maintain compliance with emission standards, making it a vital asset for fleet operators looking to improve their environmental footprint. This evolution in technology aligns with the industry’s move toward more sustainable operations, thereby enhancing the importance of tools like Cummins CalFix for INSITE in today’s world.

Key Features of Cummins CalFix for INSITE

Cummins CalFix for INSITE comes packed with robust features that set it apart from traditional diagnostic tools. These key functionalities facilitate seamless operations, making it easier for technicians to troubleshoot and repair Cummins engines efficiently.

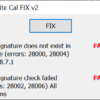

Fault Code Fixes

Determining the root cause of fault codes is crucial in any engine repair or maintenance task. Cummins CalFix excels in this area by providing quick solutions to fault codes that necessitate calibration adjustments.

When standard diagnostic tools indicate an issue, they may pinpoint a fault but often leave the technician without a clear path to resolution. CalFix bridges this gap by offering actionable insights that allow technicians to quickly address these faults at the source. For instance, if an ECM error code suggests a miscalibration, the tool enables immediate corrective action, ensuring that the vehicle can return to service without prolonged downtime.

Moreover, these fault code fixes are not just limited to addressing immediate issues. By resolving ECM problems during routine diagnostics or after repairs, technicians can foster a proactive maintenance culture that ultimately reduces the likelihood of future faults and enhances the longevity of the engine.

Advanced Parameter Adjustments

Gone are the days of limited options for parameter adjustments within engine software. Cummins CalFix gives technicians access to profound calibration capabilities unmatched by standard INSITE offerings.

These advanced parameter adjustments allow for fine-tuning of various engine characteristics, including fuel consumption rates and emission outputs. By adjusting these parameters, technicians can tailor the engine’s performance to fit specific operational scenarios, whether it be optimizing power delivery for heavy hauling or reducing emissions for urban driving conditions.

The flexibility of Cummins CalFix also means that it can help meet customer specifications more effectively. If a fleet operator requires a particular balance between power and efficiency, the advanced adjustments offered by CalFix can help achieve that delicate equilibrium, resulting in enhanced customer satisfaction and potentially lower operating costs.

Reprogramming & Flashing

Software updates are a critical aspect of maintaining optimal engine performance. Cummins CalFix simplifies this process by allowing technicians to flash updated calibration files directly to the ECM.

This feature ensures that the engine runs on the latest software configurations, which can significantly enhance its efficiency and reliability. The ability to update ECM software not only resolves existing fault codes but also enables the activation of custom features tailored to specific operational needs. For example, if a fleet decides to change its routing to prioritize fuel economy, CalFix can help reprogram the engine to align with those new priorities.

By facilitating easy reprogramming via flashing, Cummins CalFix saves valuable time and resources that might otherwise be spent navigating complex software updates manually. In the fast-paced world of diesel repair, these efficiencies translate into better service for customers and improved profits for repair shops.

Compatibility with INSITE

One of the standout features of Cummins CalFix is its seamless integration with Cummins INSITE software. This compatibility provides a comprehensive solution for diagnostics and repairs, offering a streamlined approach for technicians.

Technicians can utilize INSITE for fault code reading, diagnostics, and monitoring, while leveraging CalFix for deeper fixes and programming. This dual-layered approach ensures that all bases are covered—diagnosis, adjustment, and optimization are all managed within an intuitive workflow.

The synergy between these two software packages also reinforces the idea of holistic engine management. Instead of switching between multiple platforms, technicians can handle everything in one unified environment, increasing both speed and accuracy in their work.

How Does Cummins CalFix for INSITE Work?

Understanding how Cummins CalFix for INSITE operates is essential for maximizing its effectiveness. The workflow is straightforward but requires attention to detail to ensure optimal results.

Step 1: Connect the Diagnostic Laptop to the Engine’s ECM

The first step in using Cummins CalFix involves connecting a compatible diagnostic laptop to the engine’s ECM via a Cummins Inline adapter, such as Inline 6 or 7. This hardware connection is fundamental as it establishes communication between the laptop and the engine’s control system.

Proper connection ensures that data transactions are seamless, allowing accurate readings and adjustments. Technicians should take care to use the appropriate cables and connectors to avoid any potential disruptions in communication that can lead to erroneous readings or failed updates.

Step 2: Open Cummins INSITE and Use It to Read Fault Codes

Once connected, the next step is to open Cummins INSITE. Within the software, technicians can read and analyze fault codes and related parameters. This initial diagnostic phase is crucial; it provides insight into the engine’s current status and highlights any existing issues that need to be addressed.

Here, technicians have the opportunity to delve deep into the data and understand the nature of each fault code. Is it a recurring problem, or something new? Are there patterns associated with specific operational conditions? This analysis equips technicians with the necessary information to proceed effectively.

Step 3: Use Cummins CalFix to Apply the Required Fixes

With the fault codes identified, the technician can then turn to Cummins CalFix to apply the necessary adjustments or reprogramming actions. This phase may involve recalibrating specific parameters based on the insights gained from INSITE.

CalFix allows users to make targeted adjustments that are not possible with generic tools, helping to rectify the underlying causes of the fault codes. Whether it’s reprogramming the ECM or adjusting fuel maps, this functionality is instrumental in restoring the engine to optimal operating conditions.

Step 4: Re-Test the Engine and Verify That the Issue Has Been Resolved

After applying the necessary fixes, technicians must re-test the engine to ensure that the adjustments have been successful. This final verification stage involves using either INSITE or CalFix’s data monitoring capabilities to confirm that the previously observed fault codes have been cleared and that engine performance is satisfactory.

It’s crucial for technicians to conduct thorough testing following any adjustments. This diligence not only guarantees that the engine operates correctly but also instills confidence in customers regarding the quality of the repairs.

Supported Applications and Engines

Cummins CalFix for INSITE is versatile and supports a wide array of applications across various sectors. Its adaptability makes it suitable for many different types of engines and operational environments.

Cummins Engines

This tool is specifically designed for a broad range of Cummins engines, including models such as ISX, ISB, QSB, QSX, ISL, and ISM. Each engine type has unique characteristics and requirements, making the advanced features of CalFix invaluable for technicians working across diverse fleets.

By supporting a variety of engine models, Cummins CalFix enables technicians to become highly skilled in making tailored adjustments for each application. Understanding the nuances of different engines allows for quicker diagnoses and more effective calibrations, ultimately benefiting the end-users.

On-Highway Applications

In the realm of on-highway applications, Cummins CalFix shines in servicing freight trucks, buses, and delivery vehicles. These engines often face heavy usage and demanding conditions, which can lead to wear and tear over time.

With the ability to implement calibration fixes proactively, fleet operators can maintain higher operational standards and reduce unexpected breakdowns. Regular maintenance supported by Cummins CalFix can extend the lifespan of these vehicles while improving fuel efficiency—key factors that fleet managers prioritize.

Off-Highway Applications

Off-highway applications encompass construction machinery, agricultural equipment, and industrial engines. These machines operate under rigorous conditions and often face unique challenges compared to on-highway vehicles.

Cummins CalFix allows technicians to cater to these specific needs, ensuring that the engines deliver optimum performance regardless of the environment. Customizing engine settings to enhance productivity can result in significant cost savings for companies relying on off-highway machinery for their daily operations.

Marine Engines

The marine sector is also a prime candidate for the benefits of Cummins CalFix. Cummins-powered marine vessels require reliable performance and often face strict regulatory requirements regarding emissions and fuel consumption.

With the advanced calibration capabilities offered by CalFix, marine technicians can ensure that these engines remain compliant while delivering peak performance. The ability to adapt settings for varied maritime conditions adds another layer of versatility, making Cummins CalFix an indispensable asset for professionals working in marine applications.

Benefits of Using Cummins CalFix for INSITE

Using Cummins CalFix for INSITE brings a multitude of benefits that go beyond mere convenience. These advantages impact productivity, cost-efficiency, and the overall effectiveness of engine maintenance and repair operations.

Efficient Fault Resolution

One of the primary benefits of using Cummins CalFix is the efficiency it offers in resolving persistent engine faults. Traditional diagnostic methods can sometimes lead to trial and error, prolonging the downtime of vehicles or machinery.

CalFix streamlines this process by providing timely and specific solutions that technicians can implement immediately. This efficiency is particularly beneficial in commercial settings where minimizing downtime translates directly into reduced operational costs. Fleets can get back to work faster, generating revenue, and ensuring customer satisfaction.

Custom Engine Configurations

Another major advantage is the ability to create custom engine configurations tailored to unique operational needs. Not all engines are used in identical circumstances; therefore, having the capability to fine-tune settings according to specific requirements is invaluable.

For instance, a fleet that primarily operates in mountainous regions may require different engine settings compared to one servicing flat terrains. With Cummins CalFix, technicians can accommodate these variances, ensuring that engines are optimized for their respective environments, thus enhancing overall performance.

Cost-Effective Solutions

The financial implications of using Cummins CalFix are significant. By offering the means to fix faults that may otherwise necessitate costly ECM replacements or specialized repair services, it can lead to substantial savings for fleet operators and repair shops alike.

Investing in Cummins CalFix can be seen as a preventive measure. By effectively diagnosing and rectifying issues early, fleets can avoid the large expenses associated with prolonged repairs or parts replacements.

Seamless Integration with INSITE

The interaction between Cummins CalFix and INSITE creates a cohesive ecosystem for diagnostics and repairs. This seamless integration eliminates the need for technicians to juggle multiple platforms, thereby simplifying their workflows.

Using both tools in tandem allows for a comprehensive diagnosis followed by targeted fixes, which contributes to enhanced service efficiency. Ultimately, this synergy translates to better outcomes for customers and a more streamlined operation for techs.

Requirements for Using Cummins CalFix for INSITE

While Cummins CalFix for INSITE offers numerous advantages, there are specific requirements that users must meet to leverage its full potential. Understanding these prerequisites is essential for technicians and organizations considering its implementation.

Software and Licensing

First and foremost, users must secure a licensed version of both Cummins INSITE and Cummins CalFix for INSITE. Typically available as an add-on or subscription, these licenses grant access to the advanced features and functionalities that the software offers.

Operating without proper licensing not only limits capabilities but could also expose technicians to legal repercussions. Organizations should ensure compliance by managing software licenses diligently and keeping up with renewals as required.

Hardware

Compatibility with hardware is another critical factor. To run Cummins CalFix successfully, technicians need laptops equipped with Windows 10 or newer (64-bit). Additionally, the requisite Cummins Inline diagnostic adapter, such as Inline 6, Inline 7, or another RP1210-compliant device, is essential for establishing communication between the laptop and the engine’s ECM.

Ensuring that hardware meets these specifications enables efficient software operation and avoids technical hiccups during diagnostics or repairs. Organizations might consider investing in high-performance laptops to facilitate smoother operations.

Technical Expertise

While Cummins CalFix is designed to be user-friendly, a certain level of technical expertise is necessary to maximize its capabilities. Technicians should have experience working with Cummins engines and a solid grasp of ECM diagnostics to navigate the software effectively.

Some advanced features may require additional training or practice to use proficiently. Investing in ongoing education for technicians not only improves their skills but also enhances the overall service quality provided to customers.

Who Can Benefit from Cummins CalFix for INSITE?

The advantages offered by Cummins CalFix for INSITE extend to various stakeholders within the automotive and marine industries.

Fleet Operators

Fleet operators stand to gain immensely from the functionalities provided by Cummins CalFix. With its powerful engine calibration and fault-solving capabilities, the tool enables operators to optimize engine uptime while reducing overall operational costs.

As these vehicles are integral to business success, the ability to minimize downtime translates directly into increased productivity and profitability. By integrating CalFix into their maintenance routines, fleet operators can ensure that their engines remain in top condition.

Diesel Technicians

Diesel technicians benefit from the extended capabilities of Cummins CalFix, simplifying the troubleshooting and repair processes for Cummins-powered vehicles. Having access to advanced calibration fixes ensures that technicians can provide high-quality service to their clients, boosting their reputation in the field.

The ability to diagnose complex issues accurately empowers technicians and fosters a culture of continuous improvement within repair shops. Ultimately, this leads to better job satisfaction as technicians become adept problem solvers.

Repair Shops

Repair shops that offer services for Cummins engines can increase their service efficiency through the advanced features of Cummins CalFix. By providing calibration fixes directly, shops can attract more customers seeking reliable repairs.

Furthermore, utilizing Cummins CalFix enhances the shop’s reputation as a hub for advanced engine solutions, drawing in clientele looking for specialized services. This competitive edge can significantly impact profitability and long-term sustainability.

OEMs and Engine Manufacturers

Finally, original equipment manufacturers (OEMs) and engine manufacturers can also derive value from Cummins CalFix for INSITE. The tool empowers these entities to customize engine settings to match specific customer needs or performance criteria, leading to improved customer satisfaction.

Moreover, having the ability to tailor solutions enhances brand loyalty and sets manufacturers apart from competitors. As markets evolve, staying ahead with customization options becomes a vital strategic advantage.

Conclusion – Optimize Your Cummins Engine Performance with CalFix for INSITE

Cummins CalFix for INSITE stands out as an essential tool for professionals dealing with Cummins engines, providing unmatched control over ECM repairs and recalibrations. Its advanced functionalities empower technicians to solve difficult problems, enhance engine performance, and promote proactive maintenance strategies.

By leveraging the capabilities of Cummins CalFix, technicians can bring renewed life to engines, optimizing them for various applications while ensuring compliance with ever-evolving regulations. In doing so, they not only meet the demands of their clients but also position themselves as leaders in the fields of diesel repair and maintenance.

In a landscape characterized by rapid technological advancement and mounting pressure for efficiency and sustainability, Cummins CalFix serves as a beacon of innovation, offering the solutions needed to overcome challenges and drive progress in the industry. For anyone involved with Cummins engines—be it fleet managers, technicians, or repair shops—investing in Cummins CalFix for INSITE is a step toward achieving unparalleled engine performance and operational excellence.

📥 Contact Us:

🌐 Website: www.diagtechpro.com

📲 WhatsApp: https://wa.me/message/K6JOQMVFBGSAD1

📧 Email: di4gtechpro@gmail.com

Be the first to review “Cummins CalFix for INSITE – Powerful Engine Calibration and Fault Fixing for Cummins Engines” Cancel reply

Related products

All Product

All Product

All Product

All Product

All Product

Cummins Calterm Version 5.16 – Advanced ECM Control and Precision Tuning for Cummins Engines

Reviews

There are no reviews yet.