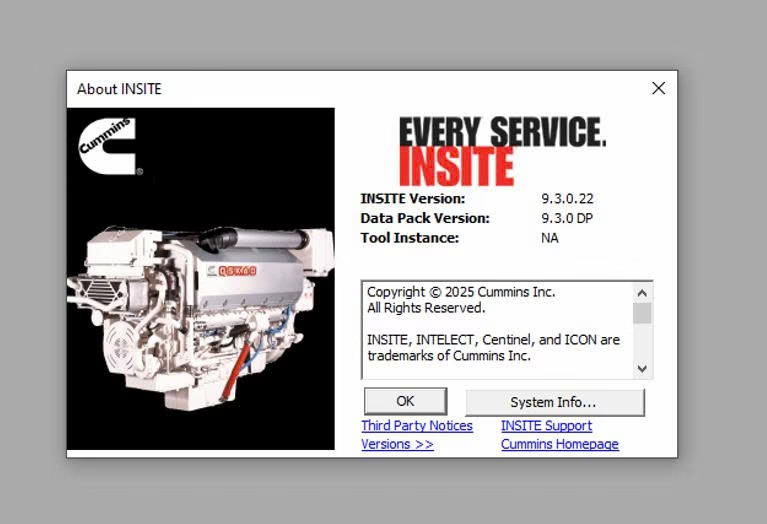

Working with modern Cummins engines requires more than basic fault reading. As ECM structures become more complex and emissions systems more tightly integrated, diagnostic software must deliver consistent communication, accurate data, and stable long-session performance. Based on real workshop usage, Cummins INSITE 9.3 has become a central tool for handling these demands effectively.

Cummins INSITE 9.3 and Real-World Diagnostic Stability

One of the most noticeable improvements when working with Cummins INSITE 9.3 is overall diagnostic stability. Compared to earlier releases, connection dropouts and session interruptions are significantly reduced, especially when working with newer ECM generations.

In daily use, INSITE 9.3 maintains stable communication during extended live-data monitoring, making it suitable for diagnosing intermittent faults and emissions-related issues that require longer observation periods.

Cummins INSITE 9.3 in ECM Communication and Data Accuracy

Accurate ECM communication is critical when troubleshooting modern Cummins engines. Cummins INSITE 9.3 shows improved consistency in parameter mapping, sensor scaling, and fault interpretation.

Technicians benefit from clearer live readings for systems such as aftertreatment, fuel delivery, and air management. This reduces the need for manual cross-checking and increases confidence when making diagnostic decisions based on ECM data.

Cummins INSITE 9.3 for Emissions and Aftertreatment Diagnostics

Emissions systems are often the most challenging aspect of modern diesel diagnostics. Cummins INSITE 9.3 handles aftertreatment diagnostics more predictably, particularly when accessing DPF, SCR, and NOx-related parameters.

Fault trees load more consistently, and snapshot data remains reliable even during complex diagnostic routines. This makes INSITE 9.3 well-suited for workshops dealing with EPA and Euro-standard Cummins engines.

Cummins INSITE 9.3 in Long Diagnostic Sessions

Extended diagnostic sessions can expose weaknesses in software stability. In real-world use, Cummins INSITE 9.3 performs reliably during long idle tests, regeneration monitoring, and repeated parameter logging.

Memory handling and session management are improved compared to earlier versions, reducing freezes or unexpected shutdowns during critical diagnostic work.

Cummins INSITE 9.3 as a Reference Platform for Modern Workshops

Beyond individual features, Cummins INSITE 9.3 functions as a technical reference point for current Cummins diagnostics. Its alignment with the latest Data Pack and ECM definitions allows workshops to standardize diagnostic procedures across newer engine platforms.

For mixed fleets, INSITE 9.3 often operates alongside INSITE 9.2 or earlier versions, but it remains the primary tool when dealing with the newest Cummins engines and updated emissions systems.

Cummins INSITE 9.3 – Practical Takeaways from Daily Use

From a hands-on perspective, Cummins INSITE 9.3 is less about introducing new tools and more about refining reliability, accuracy, and workflow consistency. These improvements translate directly into reduced diagnostic time, fewer communication errors, and clearer technical conclusions.

For technicians and service centers working regularly with modern Cummins engines, INSITE 9.3 provides a dependable diagnostic environment that aligns well with current ECM technologies.