1. The Strategic Role of Cummins INSITE 9.3 in Modern Emission Control

In an era of stringent environmental regulations like Euro VI and EPA 26, the aftertreatment system has become as critical as the engine block itself. Cummins INSITE 9.3 is not merely a code reader; it is a high-level diagnostic gateway that allows technicians to visualize the complex chemical reactions occurring within the exhaust stream.

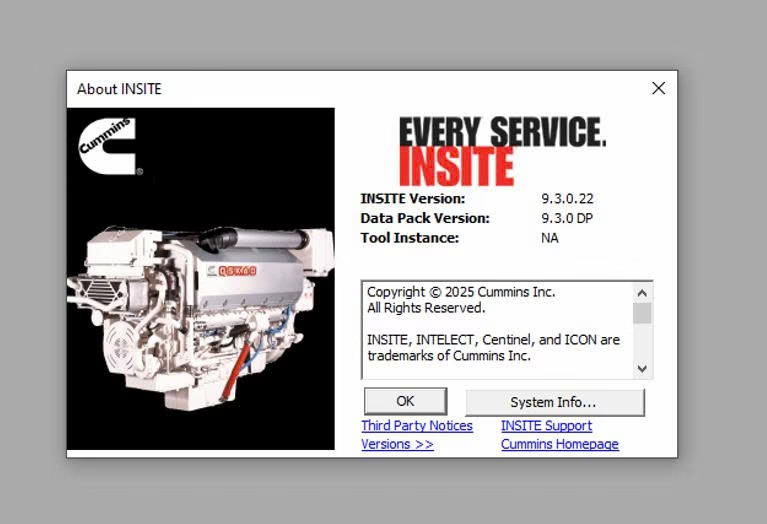

Key Insight: Version 9.3 delivers a 20% increase in data processing speed over previous versions, ensuring that real-time emission monitors reflect the most current engine states without latency.

2. Advanced DPF Troubleshooting via Cummins INSITE 9.3

The Diesel Particulate Filter (DPF) is frequently the primary cause of engine “derate” conditions. Instead of relying on guesswork, Cummins INSITE 9.3 provides a structured environment to diagnose soot accumulation and filter health through specialized visual tools and tests:

- Soot Load Analysis: Provides a precise percentage-based graphic of ash and soot accumulation.

- Deep Regeneration: Initiates a parked “forced” regen to oxidize particulate matter safely when passive cycles fail.

- DPF System Reset: Essential for calibrating the ECM after a filter cleaning or replacement.

Cummins insite 9.3 version 2026

3. Mastering SCR and DEF Systems with Cummins INSITE 9.3

Selective Catalytic Reduction (SCR) and Diesel Exhaust Fluid (DEF) systems are notoriously sensitive to fluid quality and sensor accuracy. Cummins INSITE 9.3 breaks down these complexities into manageable diagnostic steps, moving away from dense text toward interactive testing.

The DEF Delivery Verification Process

- Doser Pump Override: Manually command the DEF pump to verify spray patterns and volume without needing the engine to be under load.

- Crystallization Detection: Monitors line heaters and pressures to identify urea buildup that causes blockages.

- NOx Sensor Comparison: Real-time graphing of “Engine Out” vs. “Tailpipe” NOx levels to calculate SCR catalyst efficiency.

4. Why Cummins INSITE 9.3 is Essential for Regulatory Compliance

Compliance is a data-driven requirement. Cummins INSITE 9.3 acts as a digital auditor for your fleet, ensuring every vehicle operates within its legal emissions map while maintaining peak fuel efficiency.

- Aftertreatment Health Reports: Generate professional PDF summaries of the system’s status for maintenance records or environmental audits.

- Calibration Management: Automatically prompts for the latest ECM calibrations to fix known emission bugs and improve DEF consumption.

- Fault Snapshot Capturing: Records “freeze frame” data the moment an emission fault occurs, allowing for root-cause analysis rather than just clearing codes.

5. Conclusion: Driving Toward Efficiency and Sustainability

Mastering Cummins INSITE 9.3 for aftertreatment diagnostics allows businesses to avoid costly “part-swapping” and minimize downtime. By leveraging the software’s deep-dive capabilities, technicians ensure that engines run cleaner, last longer, and remain fully compliant with global standards.