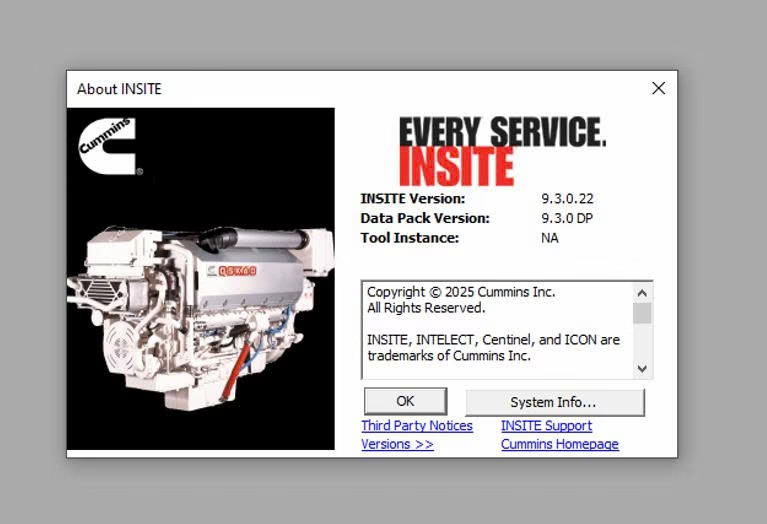

Diagnosing ECM faults on modern Cummins engines has become increasingly complex due to tighter emissions control, deeper electronic integration, and evolving ECM architectures. In real workshop environments, fault handling is no longer about reading error codes alone. It requires stable communication, accurate live data, and predictable diagnostic behavior. Based on hands-on experience, Cummins INSITE 9.3 provides a more refined environment for working through these challenges.

Cummins INSITE 9.3 in ECM Connection and Initial Fault Identification

A stable connection is the foundation of effective ECM fault handling. Cummins INSITE 9.3 shows improved consistency during ECM detection and session initialization, particularly with newer Cummins engine platforms.

ECM handshake and session stability

In daily use, INSITE 9.3 reduces common issues such as delayed ECM recognition or unexpected session drops. This is especially noticeable when switching between multiple vehicles or ECM variants during the same diagnostic workflow.

Fault code structure and visibility

Fault codes are presented in a clearer hierarchy, allowing technicians to distinguish between active, inactive, and historical faults more efficiently. This structured view helps prevent misdiagnosis caused by outdated or residual fault entries.

Cummins INSITE 9.3 for Live Data Analysis and Parameter Validation

Once fault codes are identified, live data becomes the most critical diagnostic resource. Cummins INSITE 9.3 improves how ECM parameters are streamed, mapped, and displayed during real-time analysis.

Parameter consistency during diagnostics

Compared to earlier versions, INSITE 9.3 maintains more stable parameter values during extended monitoring sessions. Sensor readings such as fuel pressure, exhaust temperature, and NOx-related data show fewer fluctuations caused by communication instability rather than actual engine behavior.

Reducing false correlations

Accurate parameter scaling helps technicians avoid incorrect assumptions when correlating multiple data points. This is particularly important when diagnosing intermittent ECM faults that only appear under specific operating conditions.

Cummins INSITE 9.3 in Emissions-Related ECM Fault Troubleshooting

Emissions systems account for a significant portion of modern ECM fault cases. Cummins INSITE 9.3 handles emissions-related diagnostics with improved predictability, especially for aftertreatment components.

Aftertreatment fault evaluation

Fault trees related to DPF, SCR, and NOx systems load more consistently, allowing technicians to follow diagnostic logic without repeated reloads or interruptions. Snapshot data captured during fault events remains reliable for post-analysis.

Regeneration and monitoring sessions

During forced or passive regeneration monitoring, INSITE 9.3 maintains session stability even over longer periods. This is critical when validating whether an ECM fault is related to sensor feedback, control logic, or operating conditions.

Cummins INSITE 9.3 as a Practical ECM Fault-Handling Platform

Beyond individual diagnostic functions, Cummins INSITE 9.3 operates as a consolidated platform for ECM fault handling in real-world conditions.

Workflow efficiency in daily use

INSITE 9.3 supports smoother transitions between fault reading, live data monitoring, and report review. This reduces repetitive steps and shortens the overall diagnostic cycle without changing established technician workflows.

Position within mixed-version environments

In workshops that still rely on INSITE 9.2 or earlier releases, INSITE 9.3 often becomes the primary reference tool for newer engines. Its behavior provides a consistent baseline for ECM diagnostics while older versions continue to support legacy platforms.

Practical Conclusion

From hands-on experience, Cummins INSITE 9.3 does not redefine ECM fault handling through new features, but through improved reliability, data accuracy, and session stability. These refinements directly impact diagnostic confidence and reduce unnecessary troubleshooting time when working with modern Cummins engines.